enviar e-mail info@xinhuatextile.com

Precisa de ajuda?+86 -13805995216

enviar e-mail info@xinhuatextile.com

Precisa de ajuda?+86 -13805995216

Is Nonwoven Fabric Cloth or Paper?

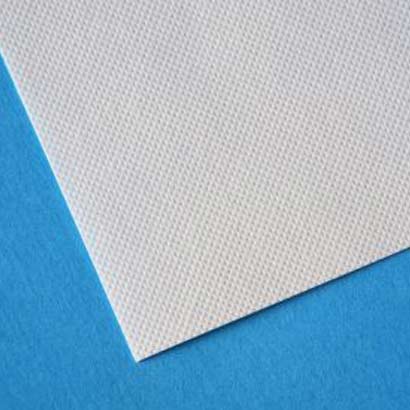

Nonwoven fabric is neither cloth in the traditional sense nor paper; it is a type of "non-woven material." It is made by directly bonding fibers into a web structure through physical, chemical, or thermal processing, without the need for traditional processes like spinning and weaving. Because it possesses the appearance and some properties of cloth, it is often classified as a fabric material.

As a new type of environmentally friendly material, nonwoven fabric is characterized by moisture resistance, breathability, flexibility, lightweight, non-flammability, biodegradability, non-toxicity, non-irritation, rich colors, low price, and recyclability. For example, common nonwoven fabrics are mostly made from polypropylene (PP) as raw material, produced continuously through a series of processes including high-temperature melting, spinning, web formation, and hot pressing.

The types of nonwoven fabrics are mainly classified according to their manufacturing and bonding technologies. Different processes result in materials with different properties, suitable for diverse applications. Common nonwoven fabric manufacturing methods include spunbond, meltblown, chemical bonding, needle punching, spunlace, thermal bonding, air-laid, wet-laid, and composite processes. These processes determine the fabric's strength, texture, and function, thus affecting its applicability in medical, filtration, automotive, and hygiene fields.

The following is a detailed introduction to various types of nonwoven fabrics:

Spunbond nonwoven fabric: Made by extruding continuous filaments from melted polymer, followed by web laying and hot pressing or heating bonding. It has high strength and durability and is commonly used in geotextiles and medical protective clothing.

Meltblown nonwoven fabric: Utilizes high-speed airflow to expel molten polymer from micro-nozzles, forming an ultra-fine fiber web. It possesses excellent filtration performance and is widely used in masks and filter materials.

Chemically bonded nonwoven fabric: By adding adhesives to solidify the fiber web, the finished product is soft and has a certain degree of toughness, often used in wet wipes and insulation materials.

Needle-punched nonwoven fabric: Uses repeated punctures to mechanically entangle the fibers, forming a dense and strong structure, suitable for carpets, automotive interiors, and geotextiles.

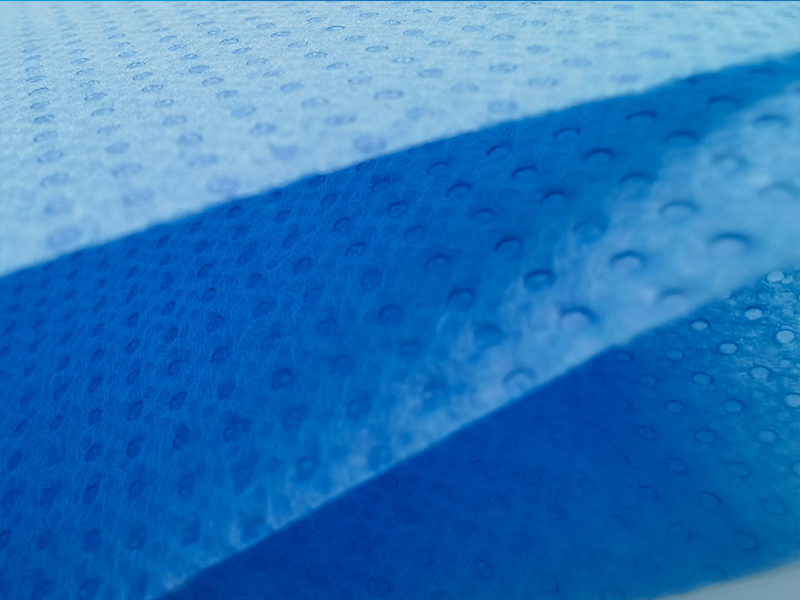

Spunlace nonwoven fabric: Fibers are entangled and formed using high-pressure micro-flows of water. The finished product combines the softness and strength of textiles and is widely used in medical wipes, hygiene products, and personal care products.

Thermobonded nonwoven fabric: Fibers are bonded together under heat and pressure using hot air or hot rolling, without the need for chemical adhesives. The finished product is lightweight yet strong and is commonly used in disposable clothing and filter materials.

Air-laid nonwoven fabric: Fibers are dispersed in an airflow and deposited onto a moving mesh belt to form a web. The finished product is fluffy and soft, suitable for absorbent products such as diapers and sanitary napkins.

Wet-laid nonwoven fabric: The production process is similar to papermaking, where fibers are suspended in water and then formed on a web. The finished product is suitable for filter materials and disposable hygiene products.

Composite nonwoven fabric: Composed of two or more nonwoven fabrics or other materials, it offers superior overall performance and is commonly used in building materials, automotive interiors, and protective clothing.

In summary, although nonwoven fabric contains the word "fabric" in its name and is similar to cloth in function and texture, its manufacturing principle is fundamentally different from that of traditional cloth and paper. Therefore, a more accurate description is that nonwoven fabric is a type of independent, flexible sheet material made through nonwoven processes, and can be regarded as a new material category between textile and papermaking technologies.

Por favor, continue lendo, fique por dentro das novidades, inscreva-se e fique à vontade para nos dizer o que você pensa.

Direitos autorais

@ 2025 Xinhua Textile Co., Limitada Todos os direitos reservados

. SUPORTADO POR REDE

SUPORTADO POR REDE

Hi! Click one of our members below to chat on